Wholesale Dealers of Optical Brightener 220 - Optical Brightener EBF-L – Subang

Wholesale Dealers of Optical Brightener 220 - Optical Brightener EBF-L – Subang Detail:

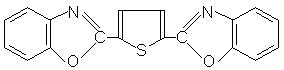

Structural formula

Appearance: Milky white dispersion

Ionicity: non-ionic

Main ingredients: benzothiazole derivatives

Dyeing shade: pure white light

Performance and Characteristics

1. Fluorescent brightener EBF-L is suitable for the whitening and brightening treatment of polyester and its blended fabrics;

2.EBF-L is suitable for exhaust dyeing and pad dyeing process;

3. EBF-L has excellent light fastness characteristics, up to level 7;

4. EBF-L has good stability to acid/alkali, hard water, peroxide and hypochlorous acid compounds;

5. EBF-L is very suitable for alkaline dyeing process.

Instructions

1. High temperature exhaustion process

Prescription: Fluorescent Brightener EBF-L 0.1-1.0% o.w.f Dispersant: 0.5-1g/L

Acetic acid adjusts pH=4.5-5.5

Process: 120-130℃×20-40 minutes

2. Continuous pad dyer

Prescription: Fluorescent Brightener EBF-L 2-10g/L Other additives: xg/L

Process: 180-185℃×30 seconds; rolling rate: 60-100%

3. One-step process of resin finishing

Prescription: fluorescent brightener EBF-L 1-10g/L silicone oil softener: 10-40g/L resin: (melamine) g/L resin catalyst g/L

Process: Drying: 130℃×1 minute Rolling rate: 40-60%; Fixation: 160-185℃×2-3 minutes

Precautions

1. The fluorescent whitening agent EBF-L must be fully stirred before use to ensure the whiteness and color consistency of the processed fabric.

2. Before whitening the fabrics bleached by oxygen bleaching, the residual alkali on the fabrics must be fully washed to ensure that the whitening agent is fully colored and the color is bright.

3. Fluorescent brightener EBF-L is a high-temperature type polyester fluorescent brightener. The dyeing temperature and setting temperature must meet the requirements of the above process to ensure the normal color of the fluorescent brightener. If you need to dye at room temperature, you can use carrier dyeing Method.

4. Fluorescent brightener EBF-L has excellent light fastness, and fabrics with special processing requirements for light fastness can be processed with this product.

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Wholesale Dealers of Optical Brightener 220 - Optical Brightener EBF-L – Subang , The product will supply to all over the world, such as: El Salvador, South Africa, Czech Republic, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.