123

Bubble film is a kind of moisture-proof and shock-proof chemical product used for packaging and filling. The bubble film has the advantages of shock absorption, impact resistance, environmental protection, tasteless, and corrosion resistance. In recent years, online shops have appeared in large quantities, which has greatly increased the use of bubble film. As a result, there are more and more manufacturers of bubble film, and the pressure of competition in the production industry is increasing. Therefore, in order to reduce costs, many manufacturers of bubble film have begun to use recycled materials for production. Compared with new materials, the cost of recycled materials reduces production costs to a certain extent and increases the price advantage of products. However, depending on the proportion of recycled materials added by the bubble film manufacturer during production, the bubble film produced will have problems such as whiteness and poor transparency. The cost is reduced, but the aesthetics of the products are not satisfactory. Therefore, most manufacturers will add fluorescent brighteners in the production process to solve the problems of poor whiteness and transparency of the bubble film. Often this is also the best solution.

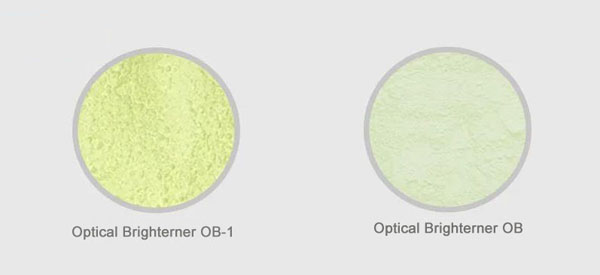

The bubble film is a soft thin-film plastic, and the addition of fluorescent whitening agent has extremely high requirements for the dispersion, stability and transparency of the fluorescent whitening agent. Because the main raw material of the bubble film is high-pressure polyethylene, add an opening agent, a special fluorescent brightener for the bubble film and other auxiliary materials, and extrude it into a bubble product at a high temperature of about 230°C. There are many types of optical brighteners, so which one is the most suitable for bubble film use? The answer is the fluorescent whitening agent OB. Many manufacturers of bubble film use traditional whitening agents or whitening masterbatch, whitening masterbatch, and other whitening products, but the products produced have insufficient whiteness and uneven color. It is prone to yellowing and other problems, because the whitening products it chooses are not suitable for bubble films.

The fluorescent whitening agent OB has good stability and dispersibility. After using the special fluorescent whitening agent OB, the bubble film can increase the original whiteness by about 10 points. The whiteness and brightness of the bubble film are well maintained, and the aesthetics is increased. It not only reduces the cost, but also increases the aesthetics. Sales and profits have naturally risen. Usage and dosage: Dissolve and disperse evenly in the product or solvent, the addition amount is about 0.02% (about 20 grams per 100 kg of product). After adding too much, it is easy to cause yellowing out. It needs to be used according to different product formulas. It is recommended to use the amount according to the guide.

Post time: Sep-16-2021