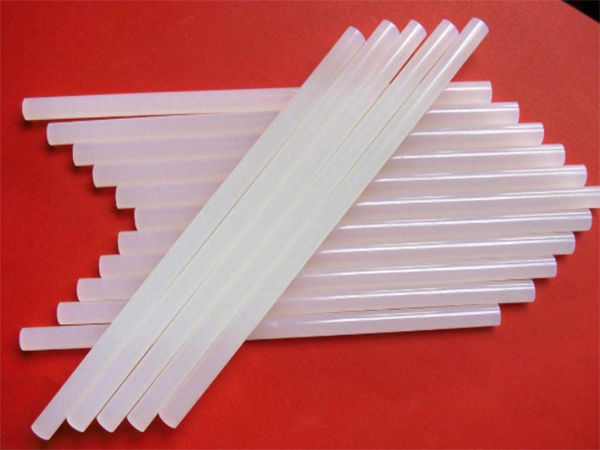

Hot melt adhesive is a kind of plastic adhesive, its physical state can change with the change of temperature, but its chemical properties will not change, so hot melt adhesive has very good environmental performance. Hot melt adhesive itself is solid, which is favored by the advantages of easy packaging, transportation, storage, simple production process, high added value, high bonding strength and fast speed.

Our common appearance of hot melt adhesive is mainly white, and some are transparent. So what should we do to make hot melt adhesive clear and white? Subang recommends adding a small amount of water during the production process. Hot melt adhesive fluorescent whitening agent.

Ethylene and vinyl acetate are the basic resins of hot melt adhesives, which are copolymerized under high temperature and high pressure, namely EVA resin. EVA resin is the main component for making hot melt adhesive, and the basic performance of hot melt adhesive is determined by the proportion and quality of resin. However, it is very important to choose the EVA melt finger. The smaller the melt finger, the poorer the fluidity and the greater the strength. The higher the melting temperature, the poorer the wetting and permeability of the adherend. On the contrary, if the melting index is too large, the melting temperature of the glue is low, the fluidity is good, but the bonding strength is reduced. The choice of its auxiliary, it is best to make the ratio of ethylene and vinyl acetate appropriate.

First, formulate reasonable formulas with different proportions of raw materials, add the prepared hot melt adhesive raw materials to the reaction kettle, and mix an appropriate amount of fluorescent whitening agent for hot melt adhesive with the raw materials evenly in the production process, generally one ton of raw materials Adding about 200g can achieve very good results.

Increase the temperature to melt it and stir well. Then cool the melted rubber in the reaction kettle to a certain temperature and put it into the running extruder. The extrusion speed of the extruder can be selected according to the different types of rubber.

The extruder squeezes the hot-melt adhesive into the water tank through a circular extrusion hole on the extrusion head. The hot-melt adhesive is immediately shaped when it encounters cooling water. The glue stick is preliminarily cooled and shaped through the first cooling water tank. The traction machine of the glue spraying machine enters the second cooling water tank, and the glue sample is fully cooled and shaped in the second cooling water tank. The running speed of the glue stick in the water tank is controlled by the extrusion speed of the extruder, so that the traction machine The pulling speed is synchronized with the extrusion speed of the extruder.

Adjust and control the relationship between extrusion speed, cooling setting speed and traction speed, and then slitting and packing the cooled hot melt adhesive into finished products. The whiteness value of the hot melt adhesive after adding the fluorescent whitening agent is obviously improved by several points, and it is not easy to yellow in the later stage.

Post time: Apr-29-2022